Generic Drug Labor Costs: What Drives Price Differences in Generic Medications

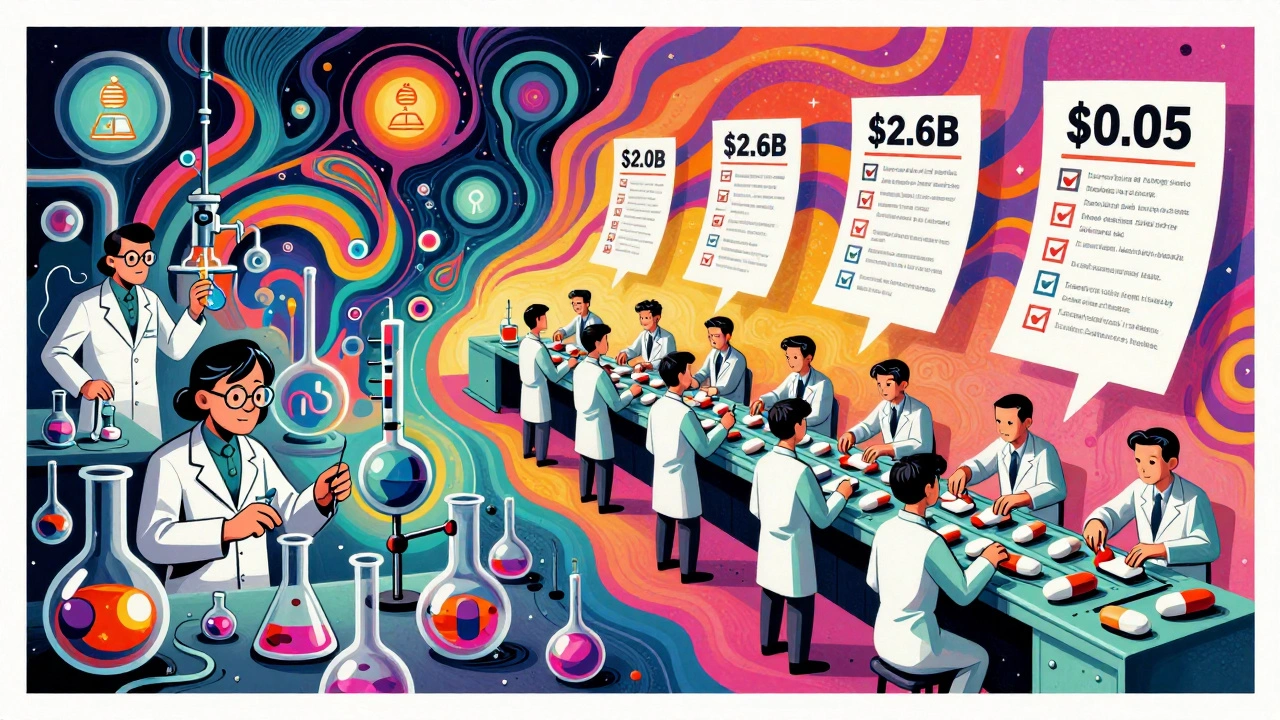

When you buy a generic drug, you’re not just paying for the active ingredient—you’re paying for the generic drug labor costs, the human and operational expenses behind manufacturing generic medications at scale. Also known as pharmaceutical manufacturing costs, it’s the hidden engine behind why some generics cost pennies while others still feel expensive. Most people assume generics are cheap because they copy brand-name drugs. But the real story is about who makes them, where, and how much it costs to run those factories day after day.

Generic drug production isn’t just mixing powders. It’s a high-precision process that needs clean rooms, trained technicians, strict quality checks, and compliance with FDA and ICH guidelines. In the U.S., labor for these roles—chemists, quality control analysts, packaging operators—costs more than in countries like India or China, where most generics are made. That’s why a pill made in a Mumbai plant can cost 90% less than one made in a New Jersey facility, even if they’re identical. But here’s the twist: sometimes brand companies make their own generics, called authorized generics, brand-name drugs sold under a different label after patent expiry. Also known as brand generic, they often cost more than regular generics because they’re made in the same expensive factories with the same labor standards. You’re paying for brand trust, not better medicine.

And it’s not just labor. The same bioequivalence studies that prove generics work like brand drugs—measuring how much enters your bloodstream—also add cost. These tests aren’t cheap. They require volunteers, labs, and regulatory paperwork. But here’s the good news: once a generic passes these tests, the price drops fast because competition kicks in. Companies that can cut labor costs without cutting corners win. That’s why most of the cheapest generics come from large-scale manufacturers in low-wage regions. But if you see a generic that’s still pricey, ask why. Is it because it’s an authorized generic? Because it’s made in the U.S.? Or because the company isn’t competing hard?

What you’ll find below are real examples of how labor, location, and regulation shape what’s in your pill bottle. From how the Hatch-Waxman Act changed the game to why some generic drugs still carry a premium, these posts cut through the noise and show you exactly where the money goes—and who benefits.

Generic drugs cost far less than brand-name drugs not because they're made cheaper, but because labor costs are lower due to scale, outsourcing, and simplified processes. Here's how production labor differs between the two.