Pharmaceutical Labor Expenses: What Drives Drug Costs and Who Pays the Price

When you see a price tag on a prescription, you’re not just paying for the chemical inside—you’re paying for the pharmaceutical labor expenses, the combined cost of skilled workers involved in making, testing, and approving medications. Also known as drug manufacturing labor costs, these expenses include chemists, quality control inspectors, regulatory specialists, and factory workers who ensure every pill meets strict safety standards. These aren’t just background costs—they’re a major reason why some drugs cost hundreds or even thousands of dollars, even when the active ingredient is old and cheap.

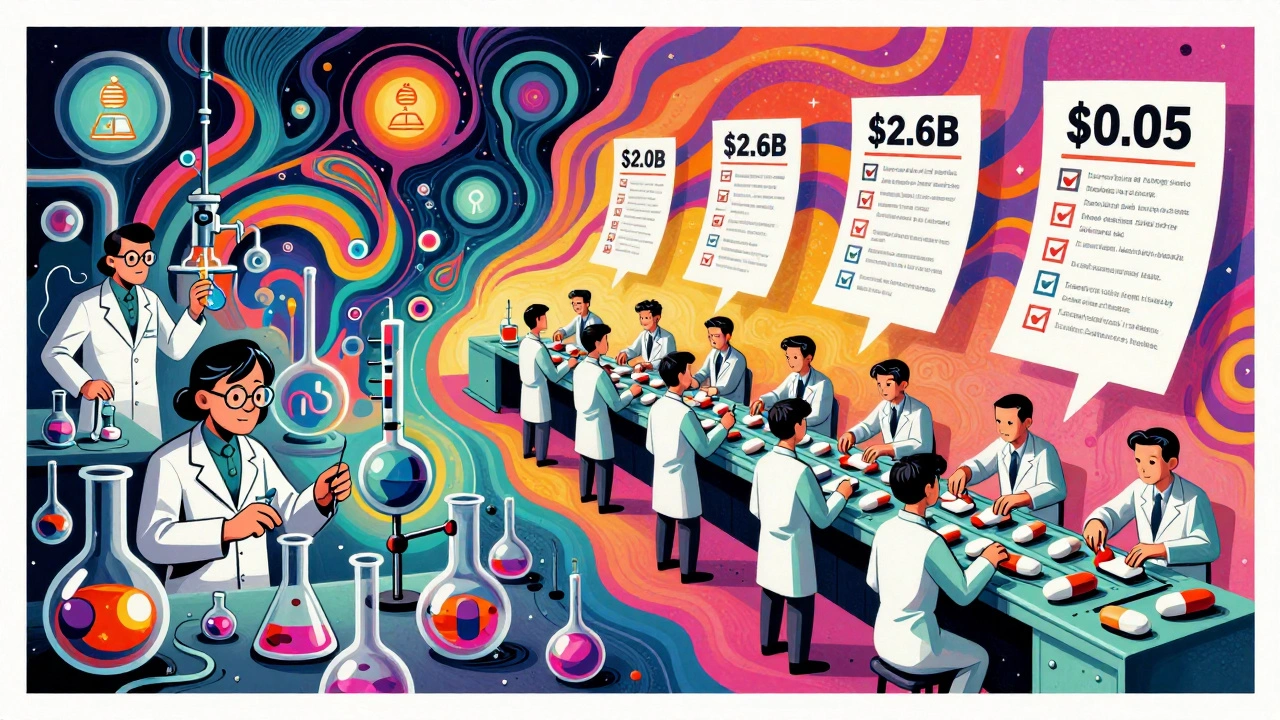

Behind every pill is a chain of human effort. Generic drug production, the process of making copies of brand-name drugs after patents expire. Also known as authorized generics, it still requires trained personnel to match the original drug’s performance down to the last milligram. That’s why bioavailability studies—like the ones the FDA uses to check if a generic works the same as the brand—are done by lab technicians using precise instruments. These aren’t automated tasks. They require skilled people who understand chemistry, data, and regulations. And those people don’t work for free. Their wages, training, and compliance overhead are baked into the final price.

Even when a drug is made overseas, labor isn’t cheap. Workers in manufacturing plants must follow FDA approval, the rigorous process that ensures every drug is safe, effective, and consistently made. Also known as pharmaceutical regulatory compliance, it’s not a checkbox—it’s a constant, detailed effort. Every batch is tested. Every record is audited. Every change in formula or process triggers new reviews. That’s why a simple switch in a supplier’s packaging line can delay a drug’s release by months. It’s not about the box—it’s about the people who document, verify, and sign off on it.

And here’s the twist: sometimes, the most expensive generic isn’t the one made in a low-wage country. It’s the one made by the original brand company itself—called an authorized generic. Why? Because they’re still using the same high-cost labor, same equipment, same quality systems. They’re just selling it under a different name. Meanwhile, cheaper generics often come from factories with lower labor standards, fewer staff, and less oversight. You get a lower price—but you also get less assurance.

So when you wonder why your medicine costs what it does, don’t just look at the active ingredient. Look at the people who made it. The lab techs running tests. The engineers maintaining clean rooms. The pharmacists reviewing dosing. The regulators reviewing files. All of them add up. And that’s the real cost of medicine—not the pill, but the people behind it.

Below, you’ll find real examples of how labor, regulation, and production choices affect what you pay—from how Australia’s PBS controls costs to why some generics cost more than others. No fluff. Just facts that explain the real price tag.

Generic drugs cost far less than brand-name drugs not because they're made cheaper, but because labor costs are lower due to scale, outsourcing, and simplified processes. Here's how production labor differs between the two.